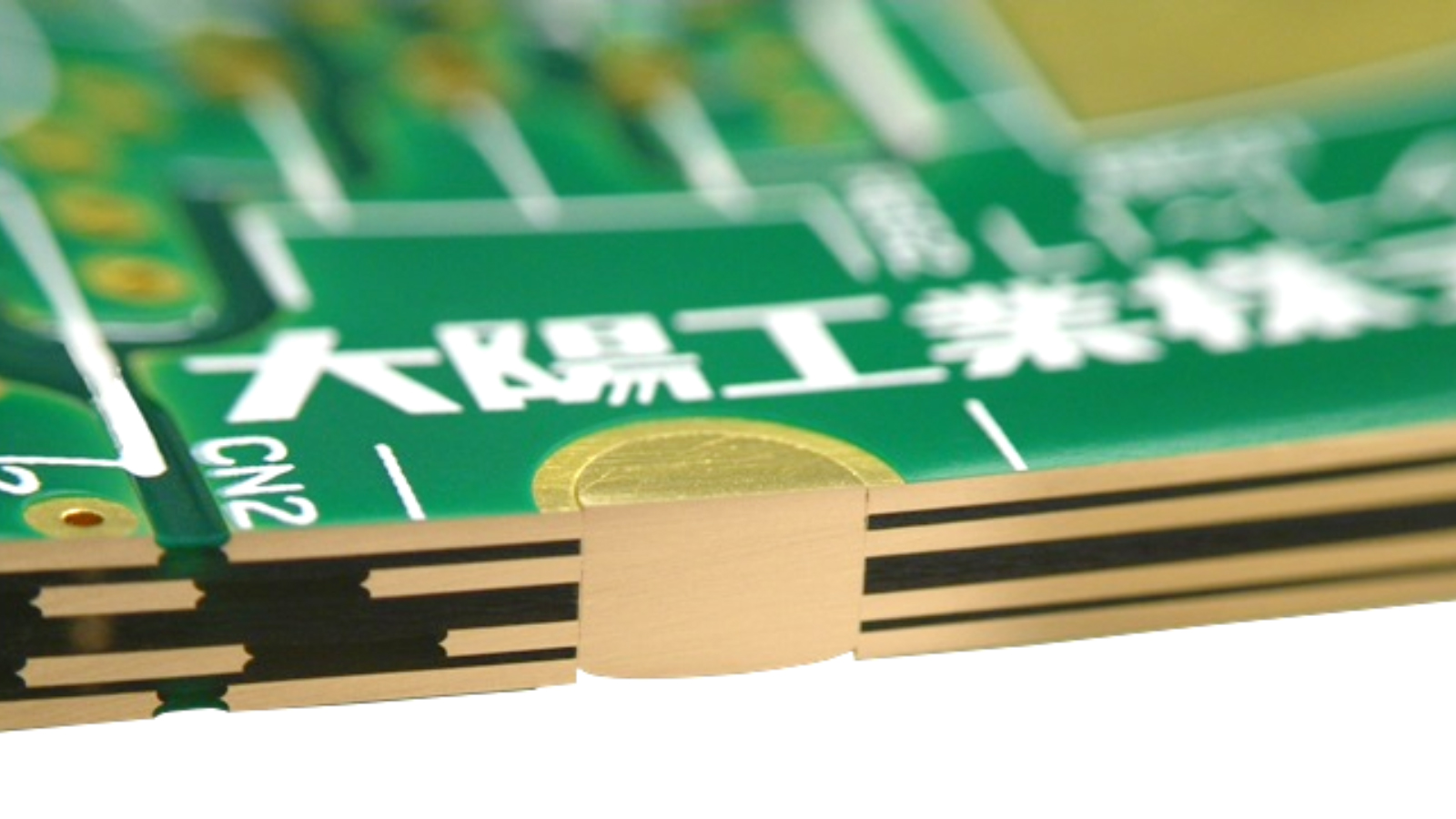

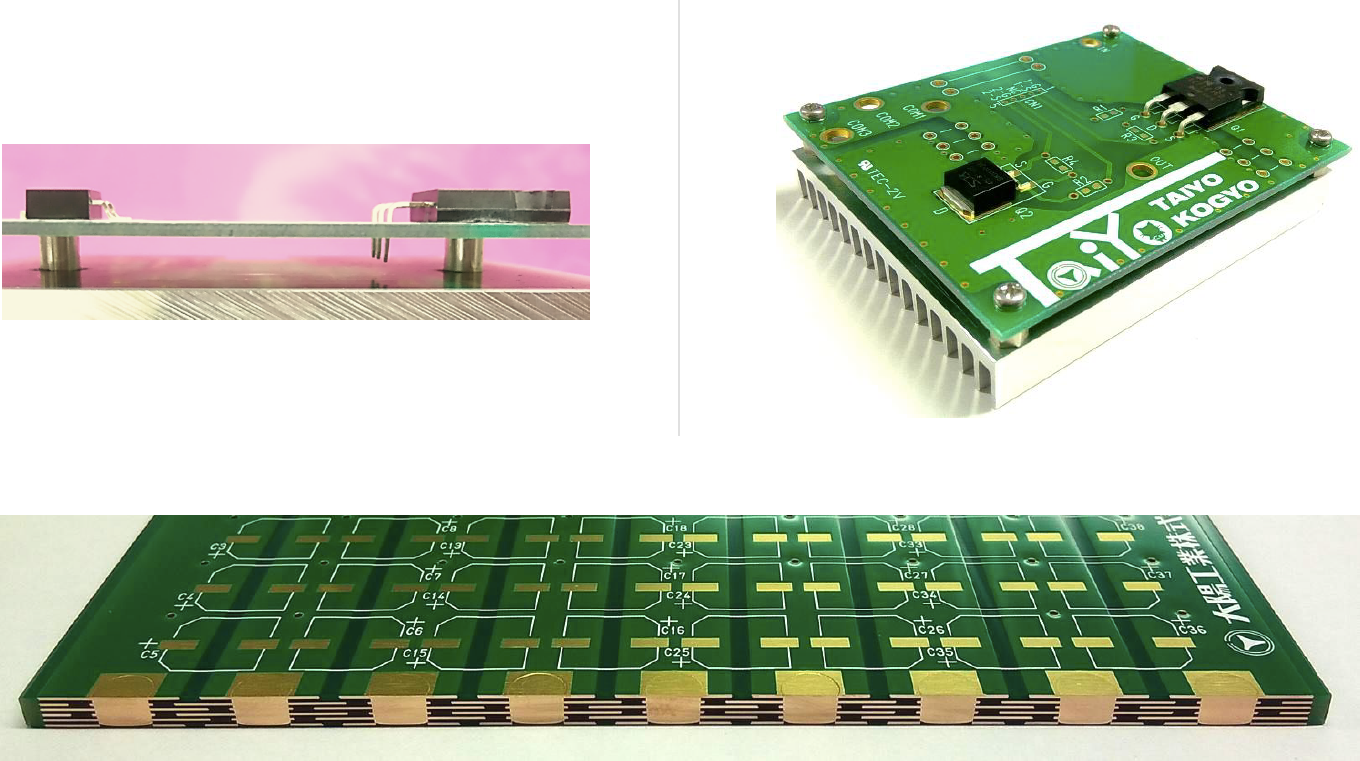

Copper Inlay PCB

Copper Inlay PCB is well recognized in Japan and is becoming a trend for Heat Dissipation PCB. Taiyo Kogyo is the first company who developed and marketed Copper Inlay PCB.

Taiyo Kogyo’s Copper Inlay PCB is widely used in many industry fields, and especially used in automotive parts which are important for human safety.

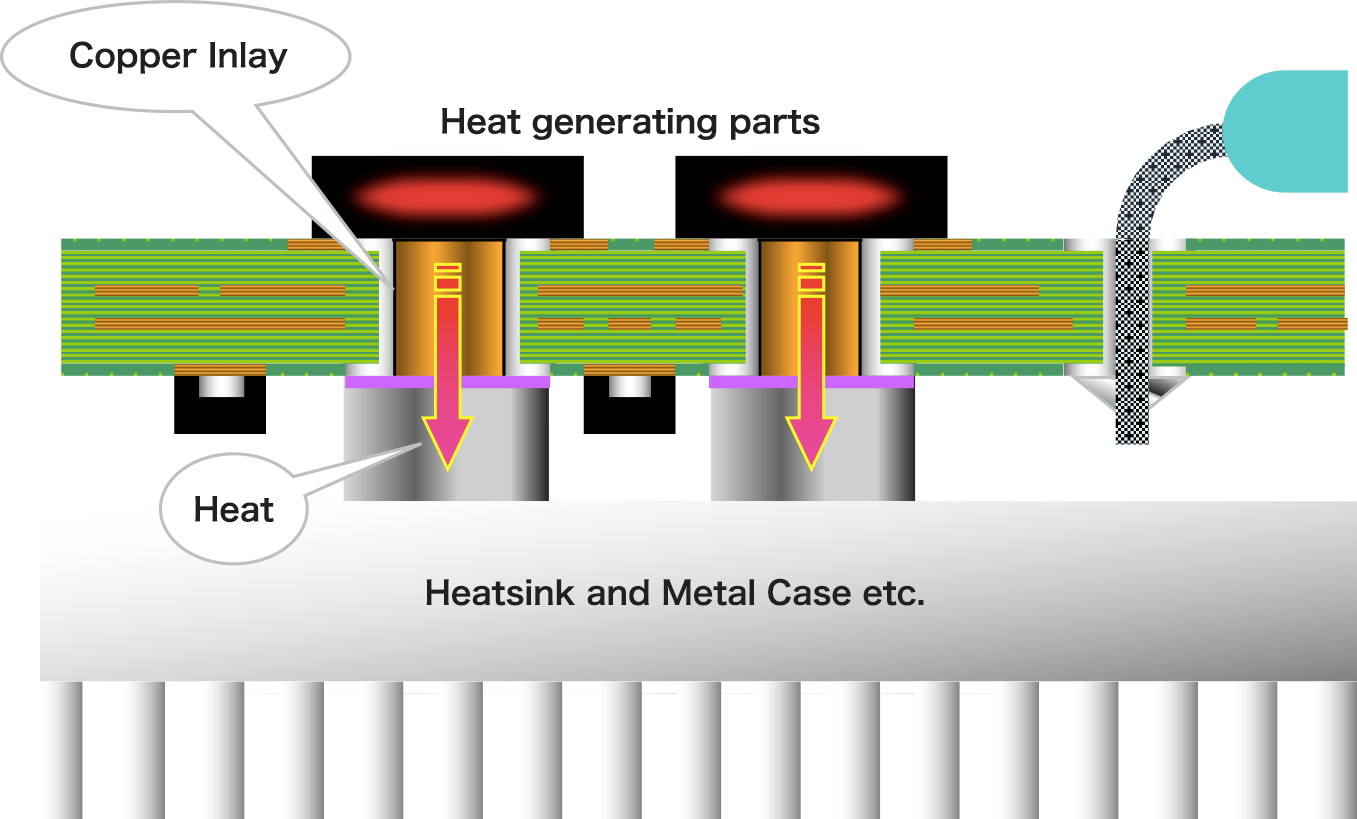

Due to higher and versatile performance of parts, heat generation of parts increases, and countermeasure for heat dissipation becomes more important in order to maintain product performance and life.

Also, miniaturization of parts makes it difficult to get natural heat dissipation from parts themselves. We need to design PCB so that heat is dissipated through traces on PCB.

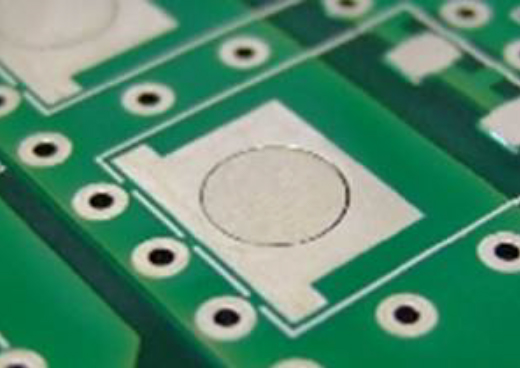

We offer "Copper Inlay PCB" which can get efficient heat dissipation by pressing copper into the board right under heat generating components.

Advantage of Copper Inlay PCB

- It is possible to dissipate heat efficiently by pressing in copper right under the heat generating components.

- Implementation of cost effective solution for heat dissipation

- Compared to Aluminum Base PCB, reliability of solder connecting part will improve because linear expansion coefficient of copper is lower than that of Aluminum.

- Compared to Aluminum Base PCB, more flexible design is possible because we can use multiple layer PCB, and both sides parts mounting board.

- Increasing circuit efficiency by more flexibility of part placement

- Miniaturization

- It is possible to satisfy QCD(Quality/Cost/Delivery) such as better reliability by eliminating fastening screw process for heat generating parts, reducing cost and reducing assembly process.

- It is possible to use same heat dissipation structure for surface mount and Lead parts.

Specifications

| Inlay diameter | 3φ / 4φ / 5φ / 6φ |

|---|---|

| Board thickness |

1.0 – 3.5mm

*In case of 6φ inlay, board thickness should be more than 1.2mm. |

Examples of usage

- Humanoid Robot

- Electric Motorcycle

- Forklift

- LED lamp

- Automotive (EV, HEV etc.)

- Power Train

- High Efficiency Server Power Supply

- Inverter

- Battery Management System(BMS)